Description

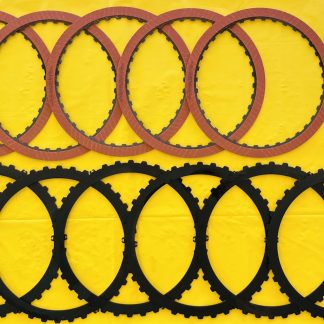

6L80E Alto 3-5-Reverse Clutch Anti-Drag Power Pack, 2006-On, 195757X-7754.

6L80E Alto 3-5-Reverse Clutch Anti-Drag Power Pack, 2006-On, 195757X-7754.

This latest 6L80E 3-5-Reverse Power Pack withstands 9 second passes along with daily commuting to work. No machining is required, but can be performed to accommodate additional clutches. This new 6L80 / 6L90 clutch pack includes 7 Kolene steels, 6 Red Eagle clutches, a backing plate, and the rubber anti-drag spacers. These spacers fit in the machined slots on the steels and provide each individual clutch the correct clearance.